It protects your conveyor or other industrial machinery when it slows down or stops unexpectedly and reacts faster than pushing emergency stop.

Function of zero speed switch for conveyor.

The zs09p zero speed switch has an adjustable set point for precise accurate speed measurement.

If the equipment speed recovers during this then the relay continues to remain on.

This high speed switch features the availability of 2 4 lane switching.

The process may be halted to prevent damage to other conveying or processing equipment.

The smart switches are ideal for any equipment that s part of a conveyor system or other shaft driven process components.

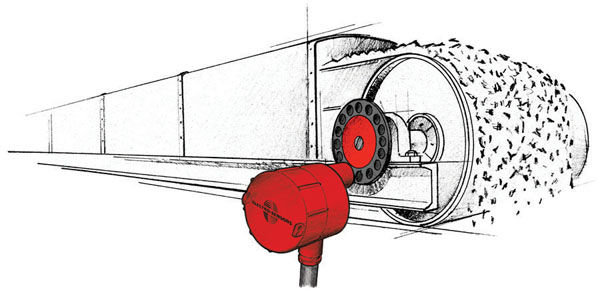

Maxigard a5000 series zero speed switch typical application.

Ratemeters and tachometers are also used to monitor belt conveyors to display the rpm of the conveyor.

When the speed sensor or speed switch detects a change in speed a signal is sent to a control panel or an alarm to alert the operator of a malfunction.

Use the zs09p zero speed switch sensor in over speed under speed or zero speed monitoring applications.

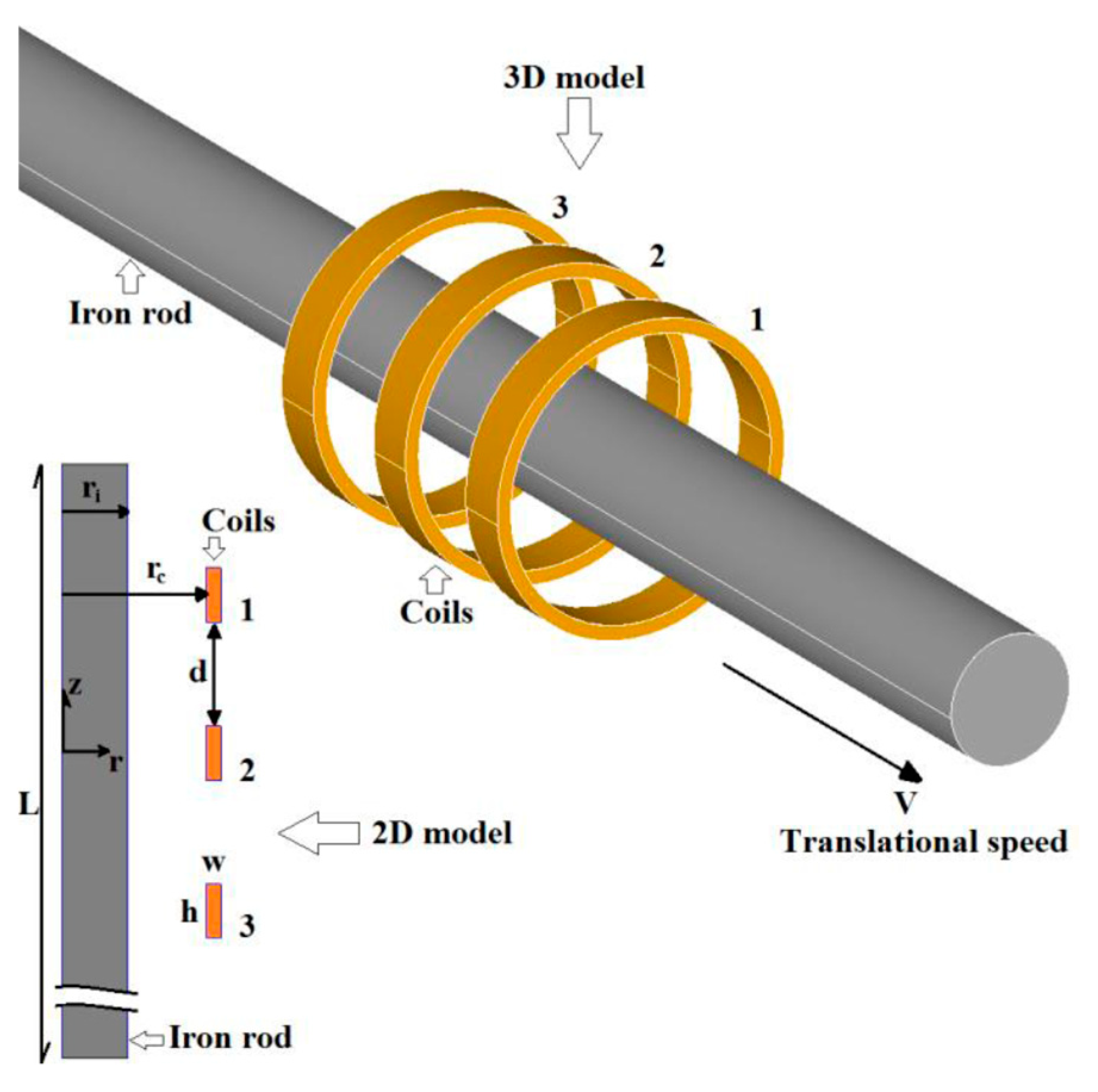

Zero speed switches zss also known as speed actuating sensing switches are used to detect whether a rotating shaft is turning even at very slow speeds in various machines conveyors power plants and in industries involving the production of cement sugar textiles paper etc.

When the sensor or switch detects a change in speed or zero speed a signal is sent to a control panel or an alarm to alert the operator of a malfunction.

The standard unit has 120 vac power input 120 vac transformer.

Dazic s electromechanical electronic and inductive proximity speed switches can let you know if equipment is running too fast too slow or not at all.

Proximity inductive zero speed stop motion and rotech encoders to monitor dangerous belt slip underspeed or stop conditions on conveyors bucket elevators and any other shaft driven machinery.

Speed sensors and zero speed switches are used to protect equipment processes and people.

Monitor a rotary airlock and screw conveyor to prove rotation for interlocked material handling equipment.

Learn more about this incredible conveyor solution at span tech and start your estimate today.

The set point is usually set at about 90 of operating speed rpm so that when a fault condition occurs the switch will trip the relay shutting down the conveyor or activating some type of audible or visual alarm.

General purpose weatherproof units and explosionproof units have 2 3 4 npt conduit openings.

Optional 240 vac power input 240 vac transformer and 24v ac dc transformer less available upon request.

The high speed switch from span tech will divide products on your conveyor system effectively without disrupting product pitch.

The unit is mounted on the conveyor by drilling 4 5 16 diameter holes.